The MICRORADAR113AN moisture meter is designed for the continuous moisture measurement of granular and powdered materials on conveyor belts, in hoppers and bunkers. The MICRORADAR113AN is suitable for the measurement of a variety of materials, including kaolin,alumina, aluminum oxide, pulp, coal, salts, minerals, sand, and other materials with intermediate to low moisture content (1 to 30%), and is easily incorporated into automatic process control systems.

The MICRORADAR113AN moisture meter is designed for the continuous moisture measurement of granular and powdered materials on conveyor belts, in hoppers and bunkers. The MICRORADAR113AN is suitable for the measurement of a variety of materials, including kaolin,alumina, aluminum oxide, pulp, coal, salts, minerals, sand, and other materials with intermediate to low moisture content (1 to 30%), and is easily incorporated into automatic process control systems.

The device is appropriate for working on conveyor belts and in bins under the condition of high temperatures and dust content, high abrasiveness and aggressiveness of material.

How The Meter Works

The meter is installed with the transmitter and the receiver placed across the material under test. An electromagnetic wave is generated by the transmitter and passed through the material, and the receiver

The meter is installed with the transmitter and the receiver placed across the material under test. An electromagnetic wave is generated by the transmitter and passed through the material, and the receiver

detects the amount of electromagnetic energy absorbed by the water in the material. Despite the complexity of the physical structure of the material, there is usually a simple linear relationship between the moisture content and the amount of energy

absorbed (at least in a limited range of moisture content). This relationship may be written in the form: N=8.7 AWrd

Where: N microwave attenuation by material, Awater absorption, W moisture content of material,

Through the channel RS485 moisture, temperature and the sensors' signals can be transmitted to the computer. The complete set of delivery of the device includes the program of storage and displaying of moisture real-time, that allows to enter into the computer, to watch, to store and to print the information on moisture for any span. A moisture measurement accuracy is from 0,15 % up to 1 % depending on a moisture range considering inaccuracies of the sample choice and moisture measuring by a standard method, for example, by oven.

The basic technical characteristics:

| Range of moisture measurement . . . . . 0,5-3% |

Basic measurement inaccuracy. . 0,15 %abs. |

|

Range of moisture measurement . . . . . 3-15% |

Basic measurement inaccuracy. . 0,5 % abs. |

|

Range of moisture measurement. . . . . 15-30% |

Basic measurement inaccuracy. . 1,0 % abs. |

| Range of moisture measurement. . . . . 30-60% |

Basic measurement inaccuracy. . 2,0 % abs. |

| Range of moisture measurement. . . . . 60-90% |

Basic measurement inaccuracy. . 3,0 % abs. |

|

Unitized analogue output (alternative) |

(4 … 20; 0-5; 0-20) mA |

|

Serial port for data transmission to PC |

RS-485 |

|

Power supply |

=24 V or 110 or 220 V / 50 Hz |

|

Power consumption |

No more than 50 VA |

|

Fulfilment of housings of units |

IP54 |

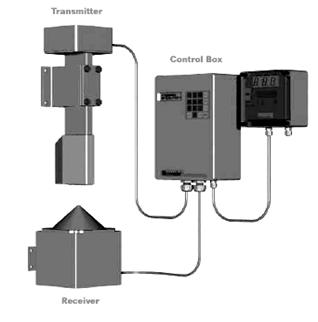

The pictures demonstrate the mounting of the sensors unit and microprocessor unit with an additional unit of indication on one of the factories manufacturing kaolin in

The pictures demonstrate the mounting of the sensors unit and microprocessor unit with an additional unit of indication on one of the factories manufacturing kaolin in

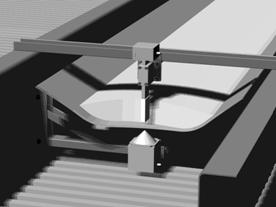

The pictures demonstrate the mounting of the sensors unit on one of the factories manufacturing coke in